Proddia IS

Structural Health

Monitoring for

Complex Structures

PRODDIA® IS, the easiest way to monitor the structural condition of complex structures, whether in the design phase or in deployed systems. Either a standalone complex structure or large set of assets, PRODDIA® IS will be the right choice.

PRODDIA® IS represents the state of art in Structural Health Monitoring for highly complex structural systems. With PRODDIA IS, complex infrastructure assets (e.g., Industry assets, Seaports, smart cities) can be equipped with advanced Structural Health Monitoring capabilities enabling remote monitoring of the structural integrity of the asset and supporting Condition Based Maintenance regimes. Advanced diagnostics and prognostics enable inspection costs to be reduced and maintenance resources to be focused where and when they are needed.

PRODDIA®IS2020 Plus -Benefits-

With applicability to any generic structure platform with any combination of structural arrangement and materials. PRODDIA®IS will have paramount impact on:

Increased Safety – PRODDIA®IS enables more operation hours with increased safety from the continuous analysis of monitored components/substructures.

Significant Reduction in O&M Expenditure – PRODDIA®IS enables more cost-effective O&M operations taking advantage of the continuous analysis of monitored components/substructures and in the state of art diagnosis proprietary technologies. PRODDIA®IS can detect, localize and estimate severity, of structural misbehavior and also estimate metrics of Systems status.

Integration with O&M Management System – PRODDIA®IS results are easily integrated on maintenance management systems enabling more effective solutions for intervention and logistics planning.

Increased Design Insight – PRODDIA®IS results can be incorporated in future design cycles of similar components or used as a verification and validation of new designs.

PRODDIA®IS2020 Plus -Highlights-

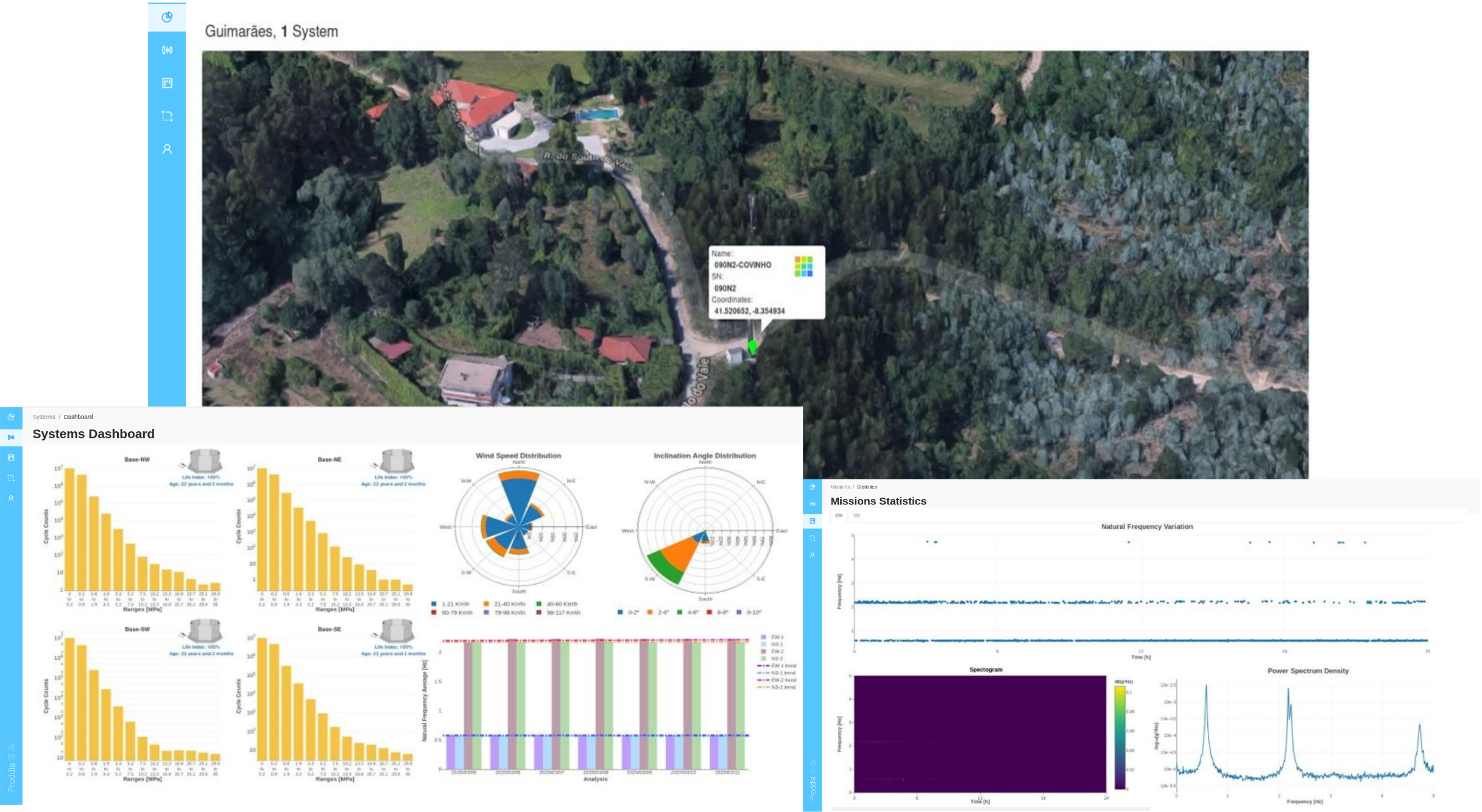

Improved analysis features – now much easier to re-run algorithms on captured data with adjusted parameters enabling more efficient what-if analyses and deeper insight into structural status.

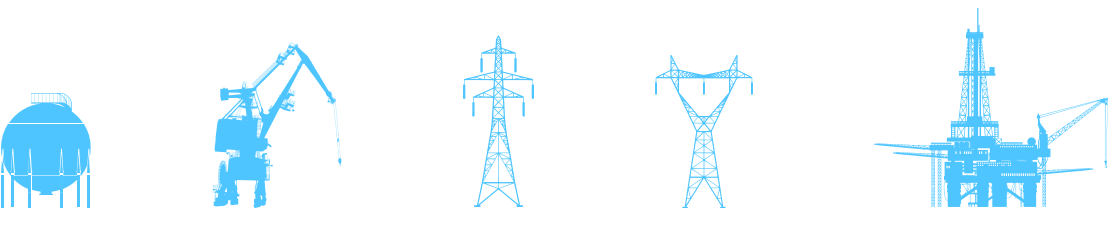

Asset geolocation display – see your assets in map view with associated structural health status.

New Particle Swarm Optimization – improved damage detection methods using particle swarm technology. Efficient and robust SHM algorithm, based on model update techniques.

Improved data storage and handling– facilitates greater interoperability and improved support for ISO 13374 (Condition monitoring and diagnostics of machines).

Extended Web Services – enhancement of the PRODDIA web services layer improves performance and scalability and enables simpler integration with existing systems (e.g SCADA, Condition Monitoring Systems, Maintenance Planning, etc).

Features

Advanced diagnosis engine – diagnosis engine includes a multi-damage scenario that significantly extends the effective damage detection area.

SHM in the maintenance loop – mobile version featuring augmented reality overlaying diagnosis results while performing maintenance operations. Project damage information on the real component, thus increasing the awareness on the structural issues, and supporting the operator to pinpoint damage with precision. This feature is especially important when working in remote conditions, with limited or no online access.

Web services integration – web services facilitate integration with external/third-party systems. Exchange Structural Health status with O&M planning tools, ERP platforms, SCADA control systems, etc.

Information extraction tools – A toolset of digital processing functions is now available for in depth information extraction. This analytical module gives the expert the power to drill down into raw signals and perform data matching analysis.

System Component tight integration – Local and global damage locations can be navigated without losing sight of where things are happening.

Manage Complex Structural Arrangements – PRODDIA®IS is implemented under a flexible architecture enabling the coexistence several components/structural subsystems and different DAQ systems. Enabling a scalable solution for a large number of configurations under the same deployment.

Explore Information at Different Levels – PRODDIA®IS enables the exploration of information at group, system and component/subsystem level. The relevant information can be visualized and explored at PRODDIA® IS Workbench in an effective and intuitive way. Visualizing damage maps and prognosis information without loss of information coherence.

Data Acquisition Systems and Sensor Network – PRODDIA®IS is capable of using a very low number of sensors to achieve very high integral component status with an extremely high degree of reliability. Working mainly with COTS solutions PRODDIA® IS works with a wide spectrum of sensor technologies and DAQ systems.

Diagnosis, Prognosis and Sensor Data Integrity Technologies – PRODDIA® IS diagnosis and prognosis are based on VS2® Core Technology, a patented technology enabling high effective combination of model and experimental data for superior diagnosis and prognosis of structural status. PRODDIA® IS can also analyze the quality and consistency of raw data from physical sensors enabling a precise distinction of sensor and structural damage. Integration with other Systems -PRODDIA® IS can integrate third-party analysis algorithms in the processing centre component and the information generated can be easily integrated into O&M systems.